Global Industrial Burner Market is growing at a high CAGR because of the increasing use of boilers in the power generation plants and increasing demand of industrial boilers in manufacturing industries which is propelling the demand for industrial burners, leading to the growth of the Global Industrial Burner Market during the forecast period…

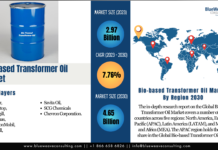

A recent study conducted by the strategic consulting and market research firm, BlueWeave Consulting, revealed that the Global Industrial Burner Market was worth USD 5.41 billion in the year 2021. The market is projected to grow at a CAGR of 7.2%, earning revenues of around USD 8.68 billion by the end of 2028.

The Global Industrial Burner Market is booming because of the increasing use of boilers in the power generation plants and increasing demand of industrial boilers in manufacturing industries which is propelling the demand for industrial burners, leading to the growth of the Global Industrial Burner Market during the forecast period. In addition, rising demand for 3D printing technology burners is emerging as a significant driver of market expansion as they save fuel and are highly cost-effective. However, difficult retrofitting procedure of industrial burners and complexities associated with maintenance, and replacement of industrial burners may act as a huge restraining factor for the market growth.

Expanding Manufacturing Industries is Driving Global Industrial Burner Market

The swiftly expanding manufacturing sector is also powering demand for industrial burners. The swelling demand for industrial gas burners in several industries like power generation, automotive, oil & gas, glass, pharmaceutical, and aerospace is likely to drive the industrial burner market growth in North America during the forecast period (2021-2028). For instance, Air Products Inc., a U.S.-based chemical industry company has introduced an oxy-fuel burner for the glass industry.

Furthermore, power plant boilers use numerous fuels such as natural gas, coal, petroleum, and biomass/wastes to yield high-pressure steam, so that plants can produce electricity. Consequently, the cumulative use of boilers in the power generation plants is also propelling the demand for industrial burners, which are an integral part of industrial boilers.

Request for Sample Report @ https://www.blueweaveconsulting.com/report/industrial-burner-market/report-sample

Increasing Use in Power-Generation Globally

The use of boilers in the power-generation plants is also propelling the demand for industrial burners, which are an integral part of industrial boilers. The growth of the industrial burner market can be ascribed to the snowballing deployment of natural gas-based manufacturing burners, particularly in Europe.

The global electricity demand is expected to rebound significantly in 2022. After deteriorating by roughly 1% in 2020, universal electricity demand is expected to rise by close to 4% in 2022. In 2022, China, one of the largest energy consumers, will hold almost 50% of worldwide growth.

According to the IEA, in the Specified Policies Situation, the global electricity demand is expected to grow at 2.1% per year till 2040, which is double the rate of principal energy demand. This would upsurge the share of electricity in entire final energy intake from 19% in 2022 to 24% in 2040.

Growing dependence on 3D Printing Technology Burners and Creation of Industrial Burners

There is an increasing growth of sophisticated liquid as well as gas burners using 3D printing technology. This 3D printing technology has helped develop many complex products and lower production costs remarkably. Burners produced using 3D technology boost fuel consumption and provide flexibility in performance.

3D technology is also used in the marine sector, where improved and technologically advanced industrial burners are used as catalyst in the process to inject diesel or oil into furnaces that ignite the boilers of the ship which produces steam and hence, turns the turbines to propel the ship. All these factors are likely to give great opportunities for industrial burners developed with 3D printing technology boosting the growth of the Global Industrial Burner Market during the forecast period.

The creation of industrial boiler plants also necessitates substantial capital investment as a prerequisite. Moreover, significant R&D, designing and engineering activities required for such projects are time and capital-intensive. Also, difficult retrofitting procedure of industrial burners and complexities associated with maintenance, and replacement of industrial burners restrain the growth of the market.

Global Industrial Burner Market – By Operating Temperature

Based on the operating temperature, the Global Industrial Burner Market has been segmented into into low temperature (< 1,400°F) and high temperature (> 1,400°F). Amidst the segmentation, the high temperature (> 1,400°F) is probable to be the fastest and largest growing segment over the forecast period. These burners are usually used in forging numerous metals and heat treatment in metals and mining, ceramics, glass, food & beverage, textile, chemical, and paper applications. The development of the market can be mostly attributed to the swelling demand for boilers, ovens, kilns and similar heating apparatus from the Food & Beverages, chemicals, metals & mining, glass, and textiles industries in emerging economies in the Asia Pacific. Hence, this is going to boost the growth of the Global Industrial Burner Market during the forecast period.

Regional Insights

Geographically, the Global Industrial Burner Market is segmented into North America, Europe, Asia-Pacific, Latin America and the Middle East and Africa. The Asia Pacific is to dominate the Global Industrial Burner Market during the forecast period, trailed by North America and then Europe.

The industrial burner market in the Asia Pacific is observing important developments in the industrial sector owing to industrialization, which has reinforced the demand for industrial burners from the countries of the region. The cumulative investments in chemicals, LNG, and mining coupled with the evolution of the internal manufacturing sector is boosting the growth for industrial burners in the Asia-Pacific nations.

Impact of COVID-19 on Global Industrial Burner Market

The unprecedented COVID-19 pandemic outbreak negatively impacted the growth of the Global Industrial Burner Market. The lockdowns imposed by the governments worldwide resulted into temporary halt of the industries throughout the world. Many production facilities completely stopped their production. This resulted in a plummeting demand for industrial burners across several industries. Moreover, several other disruptions were brought about by the pandemic such as supply chain disruptions, unavailability of the raw materials and components required for the manufacturing of industrial burners, labor shortage, etc. which also played their part in impacting the global industrial burner market.

The slowdown in economic activity and transportation restrictions in affected countries had an impact on the operations and profitability of specific global companies, mainly engaged in manufacturing and raw materials.

Competitive Landscape

The key players operating in Global Industrial Burner Market are Limpsfield Combustion Engineering Co Ltd, Andritz AG, Forbes Marshall, Ariston Group N.V., AGF Burner, Inc., Fives SAS, Weishaupt Group, Faber Burner Company, Selas Heat Technology Company, Riello S. p. A., Webster Combustion Technology, LLC, SAACKE GmbH, C.I.B. Unigas S.p.A., Oilon Group Oy, EBICO, Wayne Combustion, Baltur S.p.A., Oxilon Private Limited, Sookook Corporation, John Zink Hamworthy Combustion, Bloom Engineering, Zeeco, Inc., ALZETA Corporation, MFBurners Heat, Power Flame Inc., NIBE Group, Honeywell International Inc., WESMAN GROUP, other prominent players.

The Global Industrial Burner Market is consolidated and is dominated by a few major players that have a wide regional presence. The market leaders retain their supremacy by investing in research and development activities, incorporating cutting-edge technology into their products, and launching products with innovation. Various tactics, including strategic alliances, agreements, mergers, and partnerships, are used.

The in-depth analysis of the report provides information about growth potential, upcoming trends, and statistics of the Global Industrial Burner Market. It also highlights the factors driving forecasts of total market size. The report promises to provide recent technology trends in the Global Industrial Burner Market and industry insights to help decision-makers make sound strategic decisions. Furthermore, the report also analyzes the growth drivers, challenges, and competitive dynamics of the market.

Contact Us:

BlueWeave Research Blog

Phone No: +1 866 658 6826

Email: info@blueweaveconsulting.com